N-set wrote: N-set wrote: | Anthony, I'm sure you realize that air springs and bearings can only isolate from the structure born vibrations. Placing the tubes so close to the speakers you give them a great chance to catch strong airborne vibrations. Or will they be shadowed by the horns?

BTW What soft have you used for the visualizations? Cimatron?

|

|

Paul S wrote: Paul S wrote: | Anthony, N-set makes a good point. Also, based on the perspectives, how do you isolate the tubes from the transformers?

Best regards,

Paul S |

|

Where the amplifiers go in the room is sort of a damned if I do, damned if I don't kind of situation. I don't want them sitting in a low pressure node and would prefer them in a low pressure null, but the position of these nodes and nulls vary according to frequency and proximity to room boundaries and I am unable to plan for them in advance. So I have made the following plans to deal with the effect of vibration in the amplifiers:

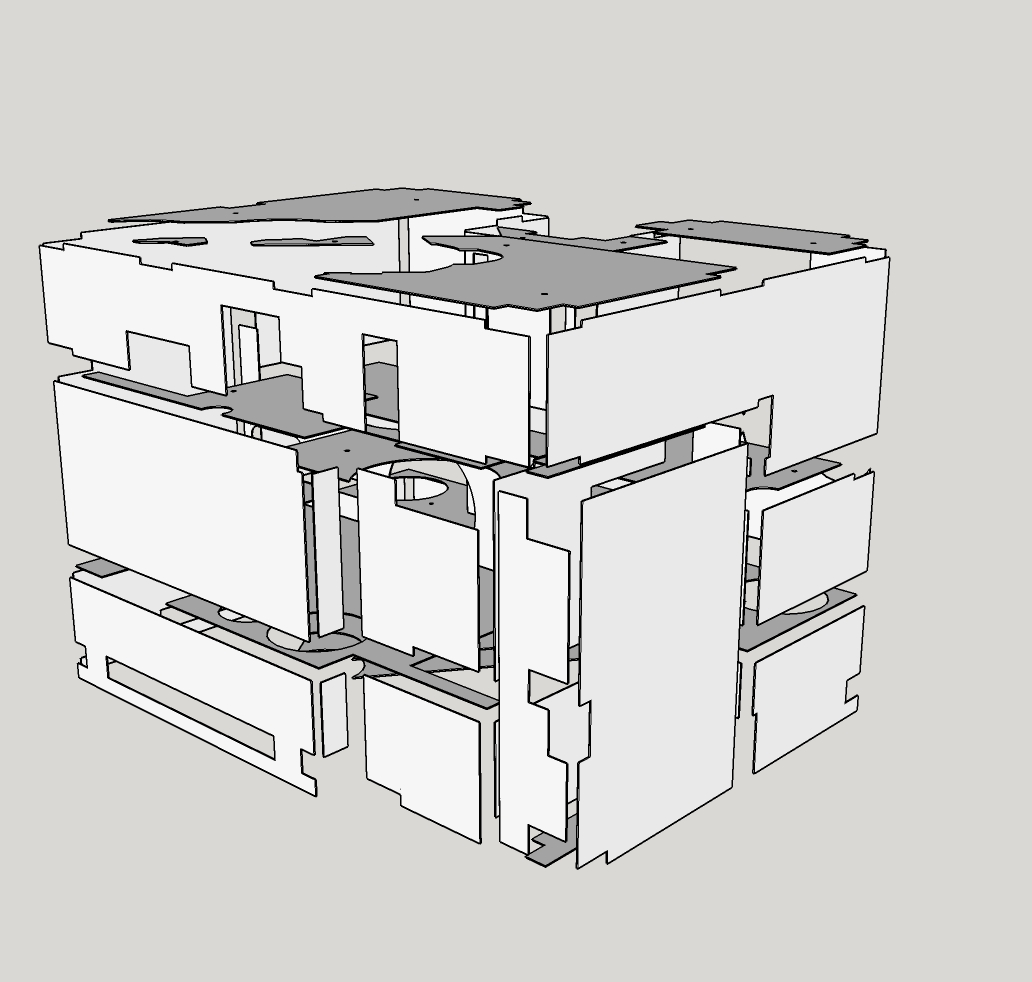

- The power supply for each mono is in a completely separate chassis situated on the floor with footer that isolate from somewhere near 15Hz with the weight loading that they have on them. The power transformers and chokes sit on non-ferrous aluminium platforms that float on appropriately loaded sorbothane bushings. This maximises the distance from any steel that they can excite thus reducing the tendency to hum or buzz. I have also lined all external steel surfaces of the PS chassis with a CLD system consisting of a 2mm thick vicoelastic damper and 1mm thick aluminium sheet. This works very well and I will use the same CLD system in the amplifier.

- The amplifier sits on a pneumatic and ball bearing isolation system designed to provide effective isolation from about 4Hz. This should be enough to isolate the amplifier itself from the movements of the room and Horn Stack. The Upperbass Horn also sits on industrial isolation footers which should isolate from a couple of octaves below any vibrations it may possibly produce.

- Inside the amplifier, there is CLD everywhere...and I mean on every possible surface with a bit of space on it...42 separate pieces of aluminium with associated vicoelastic damper in each amplifier.

- I have made the amplifiers very heavy. The best isolation above 100Hz or so comes from mass. 4mm steel external panels, 10mm steel floor, aluminium platforms 6mm and 8mm thick to provide not only rigidity but mass.

- The OPT's sit on 6mm aluminium platforms with the same sorbothane bushings that are appropriately loaded for maximum isolation. They use of aluminium internally means that the OPT's will struggle to find something to couple with given the separation distances from any steel. For example, the huge Bass OPT sits a minimum of 75mm from anything ferrous with which to couple.

Below you see the 4mm steel floor of the power supply with a 20mm gap to the 6mm aluminium platform. The platform itself is isolated using a pair of sorbothane bushings which ensure that there is no easy path for vibration to take between the aluminium platform and anything else. there is no direct physical contact between the 6mm bolt and the aluminium platform.

- The top plate through which the valves emerge is 8mm thick aluminium. There are a couple of reasons for this, one of them is that it makes a particular aspect of construction a little easier than a thinner plate, but it also makes for a relatively rigid roof on the amplifier. Immediately below this is a 4mm steel rafter onto which the valves are attached which also attaches to the 8mm aluminium top plate to form a CLD of its own, which should be reasonably effective at further dampening vibrations at the valve sockets.

So, if my plans work as well as I hope they do, the amplifier will be well isolated from structural vibrations originating in the horn stack or floor of the room. The amplifier chassis itself is very high mass and high stiffness with lots of damping that is effective from about 100Hz up, with low coupling from the internal magnetics which in turn should be suitably isolated from the chassis by the sorbothane bushings.

As far as I can see the only thing left to worry about is the effect of airborne vibrations directly to the valves from the sound of the speakers themselves. After the chassis has been made as inert as possible in order to store as little energy as possible and release it later as vibration, which is has, then this essentially becomes a placement in the room issue. There is nothing that anyone can do to eliminate airborne vibration from below about 100Hz...mass does not work and damping is relatively ineffective at these frequencies. The best solution is to place the amplifers outside the room, which is not feasible here, and even then most of the sub 50Hz will just go straight through the walls with little attenuation and still cause the valves to vibrate. The best I can hope for here is that I find a spot for the speakers in the room where the valves sit in some nice room nulls.

The horns are quite directional and frequencies above 200Hz or so will be quite attenuated behind the speakers themselves.

N-Set, I just use Google Sketch for my visualisations. I work in AutoCAD for my work, but felt that I could do this home stuff on some free software so that I did not have to buy a subscription to the Autodesk 3D modelling software.

|