|

Posted by cv on

09-08-2006

|

|

Hi Vitavox fans...

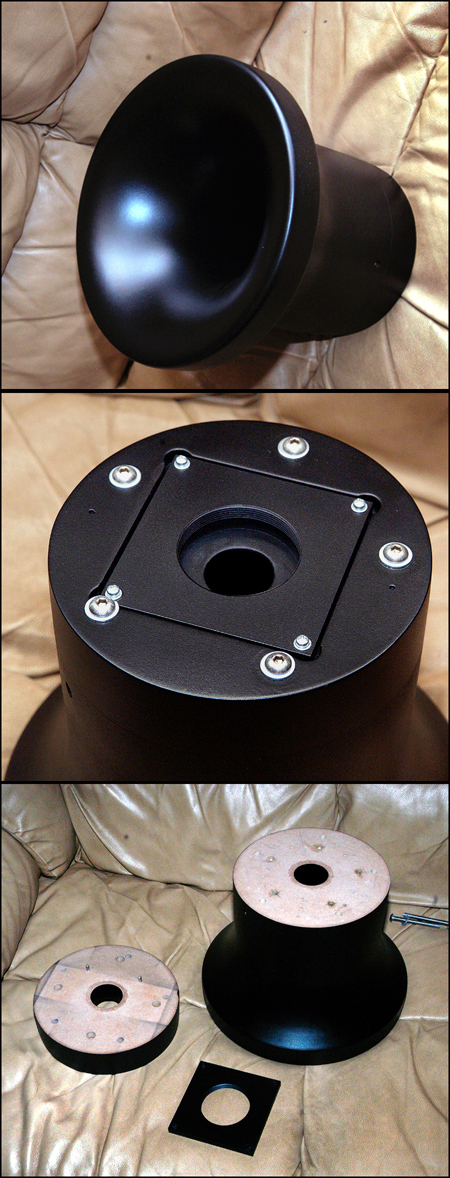

Thought this might be of interest - these are 160Hz 1.5" throat that Martin Seddon is making for me. The mounting flange isn't moulded on yet and the interior finish is alabaster like rather than glossy. I intend to damp the exterior eventually...

I'll be trying them with some different drivers whose resonance frequency is 125Hz... but they will also fit the S2 a treat.

Also need to decide whether to have them cut in half for shipping etc or not....

If anyone's interested in a group buy - please let me know.

cheers

cv

|

|

|

|

Posted by Romy the Cat on

09-08-2006

|

|

Wonderful horn, Chris. 160Hz is very-very interesting size for using S2 at it bottom knee for a lover mid-range channel. I when to 250Hz (I did not go lower because some my own reasons) but I think the 180Hz should the perfect frequency. With damping the exterior it is complicated. It is absolutely necessary sonically but any damping that I have seen so far make the horn to look ugly. That is why I usually advocate the thicker walls – although it makes the horns more expensive to make and less “airy” looking but it make then to sound better.

Chris, please keel posting your observations when you get the horn and will teach to sound in your room. It is very educational….

Regarding “cut in half”… Well, how frequently do you order the horn of the given side? I bet that you will have one 180Hz over the period of your life. (!) Does this fact suggest that it makes sense to pay once a little more and do not sacrifice the result? Well, the paradox is that in order do not sacrifice the results it does make sense to cut the horns (:-)… but not for the sake of cutting the shipping cost.

You see if you are wiling to try “some different drivers” then they all have different throat seizes. The transmission between the throats and driver output is very critical part it is should be perfect and without any steps. So, how to do it? The most effective and elegant way is to target the horn to 2.5” for instance and then introduce an interchangeable extension of the length enough to finish the given profile at the necessary diameter. Unfortunately it will do little to help with shipping expenses, as it should be cut practically at the very end. Also, it is practically not implementable with the thin-wall-horn as you would need “mass” and sire to implement some attachment mechanism. Juts for sake of illustration here is how John Hasquin has done in my 400Hz horns. Frankly speaking it is the most versatile implementation of the concept that I have ever seen.

I think the idea is very much worth to be embraced.

Rgs,

Romy the caT

|

|

|

|

Posted by i_should_coco on

09-09-2006

|

Hi all,

They look fantastic! I've been talking to Martin recently about some horns for my S2s and he mentioned he was developing some 160Hz horns. I guess these must be them!

I already have some of the smaller 340Hz Azuras, but they have 1" throats and I've been using those with Coral M-100 drivers (I didn't have the S2s ate the time). I don't want to cut them to fit S2s I case I mess them up. I'm currently using the S2s with some borrowed CN157 horns just to get a taste of what they sound like and while I can hear that the S2s are way better than the Corals, the horns just don't do it. The other Azuras I have sound so natural and "un-horny" in comparison.

I guess these would work nicely from 300Hz to ??? Can the S2 really go that low? I've heard differeing opinions....

Would defintely be interested in a group buy? I'm in the UK.

Cheers,

Pete

|

|

|

|

Posted by guy sergeant on

09-09-2006

|

I might also be interested and am in the UK. Any rough idea of price?

rgs

Guy

|

|

|

|

Posted by NBC on

09-09-2006

|

Hi Guys,

An idea I've had for damping thinner horns in a more or less aesthetically pleasing manner is to house the horn in a Sonotube rigid cardboard cylindrical concrete former, and then apply the desired damping material inside the Sonotube.

This could be done in such a way that the modification is reversible, with the horn staying in more or less intact condition. For instance, a thin sleeve material could be overlayed onto the outside of the horn body before the damping material is applied, poured or sprayed.

The only possible downside I can foresee is that the straight-sided cylindrical profile will interact 'differently' (not necessarily worse) with the nearby drivers. For example, with a significantly shorter acoustically time-aligned tweeter or midrange horn, the sound will hit the first reflection surface of the adjacent longer/wider cylinder-encased horn. Even without such an enclosure and using just a naked horn, however, there are still first reflection points off the longer/wider horn(s) to deal with, albeit with a different, less uniform pattern of first reflection points.

The Le Cleac'h horns have very large diameter mouths, presenting an additional challenge in terms of dealing with the *inter* horn first reflection points in acoustically time-aligned Multiway horn systems. Whilst minimizing these first reflections off the long horn body and large bell via increased inter-horn spacing, center-to-center distances between the horns may increase the distance at which the system can become integrated into a convincing homogeneous point source.

Neil

|

|

|

|

Posted by Romy the Cat on

09-09-2006

|

i_should_coco wrote: i_should_coco wrote: | | I guess these would work nicely from 300Hz to ??? Can the S2 really go that low? I've heard differeing opinions.... |

|

Pete,

How low the S2 really go? It is a little bit complicated. First of all there is an objective S2 ability to go low and second there is a reasonable limit were it makes sense to use it.

Objectively it is very simple to test the S2 ability to go low. Take an S2, with clean gap and well aligned diaphragm. Take a generator and feed the S2 with valve at I would say 1.5V. Slowly move across the frequencies form 1000Hz down. At ~450Hz you begin to detect minor inflections of resonances. You will be able to deal with them by using different methods but you will win a couple dozen of Hz, no more. At 350Hz the S2 still will do sound but it will be with quite lot of buzzing in it. Surely, the crossover and the lower voltage would help in the real world not to mention that this buzzing is NOT really disgusting sounding, quite in contrary (if you made those experiments then you will know what I mean). However, here is where the reasonability limit kicks in (the new plastic suspension behaves for the buzzing perspective better at sub 500Hz level but less interesting Sonically below 500Hz)

If you use S2 at 350Hz then the horn should be no less than with 150Hz -160Hz flare, if not then you get honk. 150Hz is a big ass horn, really big. Still, you need two more, relatively large horns atop (for MF, as the 150Hz horn do not do uppers MF range well) and for bottom (as the amplitude of your S2 will die at ~350Hz-400Hz and no LF direct radiator will be able to do so high, performing good enough to be mated with the horn). So, you might have difficulties to position this assembly, unless you have really large room. However, if you do have a large room, than you need to drive your drivers (including the S2 at 350Hz) with more voltage, increasing the buzzing distortion on the S2 driver. Add to this the fact that S2 is alnico driver that has tendency to be demagnetized from excessive voltages or excessive LF. Add also to the fact that S2’s sound at 300Hz, even disregarding the buzzing, not really as good as it sound at 700Hz. The driver enters at sub 500hz in the “suffocation mode” and I really do not feel it worth to be used in there.

I think 450Hz with second order in 180hz horn is a reasonable minimum save zone (with tractrix curve, I do not know how it will equate to the Le Cleach’s profile). You might get little more from Vitavox S2 but in order to evaluate how good it might be the Sound from the bottom of S2 should be viewed in context of what the upper knee of the lower frequency channel is capable off. It is MUCH easier to get excellent Sound at 300-400Hz form a larger horn and with a driver then to squeeze the last drops of Hertzs out of the dieing S2 driver.

Rgs,

Romy the Cat

PS: Pete, my site dispatches email reply notifications. The email address you supplied in you registration became unavailable and reply keep bouncing in the queue. Please update you profile with your current email.

|

|

|

|

Posted by i_should_coco on

09-09-2006

|

Hello Romy,

Thanks for the great explanation, I'm a newcomer to horns, so please treat me gently ;-)

Very interesting info, so in essence there are two limits, the real "hard" limit, where you risk damage to the driver, and the "sensible" limit, below which is cease to sound good. I'm intrigued by your comment that the buzzing below 350Hz is not "disgustng" sounding, I would have though any buzzing is a bad thing? I take it that this test is without a horn to load the driver? Currently, I cross (2nd order) at about 550Hz using the CN157.

I confess that I actually have two pairs of S2s (which have different diaphragms, one pair has the metal surrounds and the other pair, plastic) and I was hatching a scheme where I could use both of them, so I was thinking one pair from 350Hz to say 3Khz, the second pair from 3kHz to 12kHz (which I belive is pretty much the upper limit for the S2) and probably a tweeter above that. With the CN157, the S2 definitely needs a tweeter. From what you say above, 450Hz would be more realistic for the low end I guess? I see in your "fundamental channel" experiments, you appear to be doing something similar, which give me hope.

I do have a real headache trying to figure out what kind of bass solution to use. I have built some prototype mid-bass horns with AK151 drivers, but they're enormous, so I can't keep them long-term, because they just don't fit in my lounge. I was mooting the idea of some sort of folded horn, but they would have problems getting high enough I suspect, which is why I was hoping to get more from the S2. Any suggestions on how to integrate a sensible bass/mid-bass solution? - I have a pair of sub-woofers which I can employ below 100-150Hz if I drive them actively.

Cheers,

Pete

P.S. E-mail fixed.

|

|

|

|

Posted by cv on

09-09-2006

|

Allo fellas,

Regarding pricing, best if you check with Martin; I know what I'm paying but I had to commission them specially - I know a hell of a lot of work went into making the mould, jigs to support the mould, etc etc. Actually the 340s were my commission too, so nice to hear that there are others in use in the UK :-)

To address some of the other points:

1) Cutting

Martin thinks he can cut them and mould a flange on to each part such that the join will be perfect, or at least, of the same order as eg textured paint. I'm therefore not too worried about any detrimental sonic effects.

Obviously it makes shipping and transportation a pain. Uncut implies sea transit which will take a few months. Martin mentioned that he almost didn't manage to get them out of his estate car, which would have resulted in the coolest car stereo ever.... To be honest, despite what I said earlier, I'm more worried about being able to get them in and out of the flat than the shipping expense.

2) Different throat sizes

Martin can mould on any throat size desired. I have S2s and RCAs which are also 1.5" so decided to keep it simple, though Hasquin's approach is obviously great for flexibility and much more applicable to wooden horns such as his... the idea for the horns was more motivated by use with the RCAs, which Steve Schell reckons are very happy at 300Hz 1st order or 250Hz 2nd order. But I am as interested in hearing what the S2 can do down low, c 450Hz, on such a horn.

3) Damping

Had *exactly* the same idea as you Neil re Sonotube. Was thinking of a layer of plaster of paris or sand/resin around the horn, then filling up the remainder of the tube with expanding foam.

My guess would be that reflections off the sonotube are probably less damaging than from the backs of the unmounted horn, and it would be easy to have an absorbing layer around the tube, but I hear you about the driver spacing issue. More "ways", as with Romy's latest setup, are clearly a plus from this standpoint.

4) The sad part of the story...

They were commissioned a while ago, before my plans involved moving to NYC with work... I'm not sure if the horns will fit the NY apartment... going to attempt a mock up and discuss with the girlfriend. She thinks they look terrific (can't disagree) so we shall see, but they may have to stay in the UK, in which case I will get to play with them on London visits, weekends and school holidays. It's a shame because the (studio) in the UK is 25x25ft and would be the perfect size for a balls-out system to challenge the Cat's.

So at the moment, the most likely delivery point is the UK. Are you guys able to email me from the site?

Cheers

Chris

|

|

|

|

Posted by i_should_coco on

09-09-2006

|

Hello Chris,

Yes, the 340s are superb. Martin suggested I cut them myself, but they're very nicely made and I really don't want to make a pig's ear of it. I wish I'd had him make them with an "adapter" so I could use larger format drivers. I didn't have the S2s at that point though. Hindsight is wonderful....

These look like they could be really good, so if they're coming to the UK, I'll be in. Can't see a way to e-mail you via the forum though.

Cheers,

Pete

|

|

|

|

Posted by Romy the Cat on

09-09-2006

|

i_should_coco wrote: i_should_coco wrote: | | ….so I was thinking one pair from 350Hz to say 3Khz, the second pair from 3kHz to 12kHz (which I belive is pretty much the upper limit for the S2) and probably a tweeter above that. |

|

Pete, I feel that the more reasonable use if a 3 pairs of S2 is do not implement the judgmental crossover point but to us the idiosyncrasy of the currently existing in S2 none-linearity. Go to “Knowledge Tree and find the Vitavox Survival Gigue. It depicts in details what the S2 does. Also, and I do not want to sound like a principle in a catholic school but I try to keep the threads of this site more or less bind to the subject of the thread. So this thread is about the CV’s 160Hz horn…. Sorry for being anal but I think you yourself will be benefited is the threads will be on the atomic subjects.

i_should_coco wrote: i_should_coco wrote: | | I do have a real headache trying to figure out what kind of bass solution to use. |

|

Welcome to the club… :-)

Rgs,

Romy the Cat

|

|

|

|

Posted by Romy the Cat on

09-09-2006

|

cv wrote: cv wrote: | | Obviously it makes shipping and transportation a pain. Uncut implies sea transit which will take a few months. Martin mentioned that he almost didn't manage to get them out of his estate car, which would have resulted in the coolest car stereo ever.... To be honest, despite what I said earlier, I'm more worried about being able to get them in and out of the flat than the shipping expense. |

|

Well I have a good solution for you. The Australian Martin might plug the throat of the horn, fill up a half of it with sand…. and use the alternative shipping options….

cv wrote: cv wrote: | | the idea for the horns was more motivated by use with the RCAs, which Steve Schell reckons are very happy at 300Hz 1st order or 250Hz 2nd order. But I am as interested in hearing what the S2 can do down low, c 450Hz, on such a horn. |

|

Hm, I would suggest to take with suspicion Steve Schell’s comment about the RCA’s happiness at 300Hz. Steve is audio historian and he does not specialize in Sound. It might be possible to drive the RCA at 300Hz but no one person who has mind would not be doing it. What happens is the output tube of your SET pops and you loose your RCA diaphragm? To use a different diaphragm? Sure but it is not the RCA driver anymore and for the historian minded people it would be betraying… Anyhow, I think to starch a MF driver to sub-300Hz is a summit of foolishness. 300Hz driver in order do not have honk should be sitting in too large horn that will too heavily attenuate HF and eat transient and tonal discrimination (that RCA has problems to begin with).

cv wrote: cv wrote: | | So at the moment, the most likely delivery point is the UK. Are you guys able to email me from the site? |

|

Nope, there is no way for the members to see your emails unless you explicitly enable it in you profile. The profile pages on my site are not spiderable.

Rgs,

The caT

|

|

|

|

Posted by cv on

09-11-2006

|

Ah, methinks you do Steve Schell a disservice Romy. He suspects that my RCA drivers have hairline cracks in their paper voice coils (certainly, one of the drivers is making strange noises) so I am getting his new replacements which are made of carbon fibre, not phenolic as of yore. They tried phenolic originally and felt they obtained better results with carbon.

So, whilst Steve and Rich may have a strong respect for the past, they are not complete slaves to it in their pursuit of Sound.

Therefore, I still hope the RCAs will do well on the 160s. If not, then the S2s, and a higher x/o, it will be.

Love the cartoon in any case!

cheers

cv

|

|

|

|

Posted by Romy the Cat on

09-11-2006

|

|

Chris, I do not do “service” to anybody. I said what I said and what I feel

I do not use phenolics in MF and as I understand nether Steve Schell. In fact I do not think that it would be a good choose for MF driver. The carbon fiber from my point of view is very controversial material and particularly for a driver that pretend to do HF. If you experimented with tonearms then you might observe that as soon the pipe has any carbon fiber in it then it deaden the arm sound at inhumane degree. I’m afraid that carbon fiber would be too much self-absorbing material and will eat a lot of “tonal idiosyncrasy” and dynamic transients. It is in a way how the Schell’s drivers sounded and ironically it was how the original RCA sounded when I herd them (although it was too difficult to say anything defiantly about the originals RCAs as that installation was way sub-capable)

Sure, no one would be able to say it defiantly but you will be and it looks like that you will be very soon. When I spoke with Rich about it I proposed to make their carbon cone alike the Görlichs drivers with aluminum external impregnations. I think it would make then interestingly-ringy…. In the end, if Steve Schell do pursuit more interesting sound then “juts Sound” then it feel that current Schell carbon fiber cone for MF driver is not his last one…

Rgs,

Romy the caT

|

|

|

|

Posted by NBC on

09-13-2006

|

Here are some photos of Martin Sedon's 204Hz and 340Hz Le Cleac'h horns, which likely have more reasonable shipping charges and fit through doorways, etc. better than the 160Hz version. They have a T-factor (expansion rate) of T = 0.8, which was recommended to Martin by Jean-Michel Le Cleac'h. Here are some photos of Martin Sedon's 204Hz and 340Hz Le Cleac'h horns, which likely have more reasonable shipping charges and fit through doorways, etc. better than the 160Hz version. They have a T-factor (expansion rate) of T = 0.8, which was recommended to Martin by Jean-Michel Le Cleac'h.

You can find Martin and Jean-Michel's email addresses on the internet if you look around on google.

Interesting related post by Romy: http://www.goodsoundclub.com/TreeItem.aspx?PostID=1851

Regards,

Neil

PS: Romy, if these photos are too large for your taste, I can resize them. But one can certainly see a lot of detail of the horns texture and construction in this way.

Some good comments from Romy I pasted from elsewere on this site:

"One more thing, you said that “they sound better when crossed over above 800Hz.” Any compression driver sound better when you have 1-2 octaves under it’s lower knee and when the driver (and horn!!!) is not overwhelmed with the lover mid range. (It I what most ignorant people love to do: to peruse as low crossover point as possible for their compression drivers driver mid-channels and eliminate the upper bass drivers. This is a big mistake and I consider that upper bass channel is the key for any horn loaded installation)"

"So, if you suggest that it “sound better when crossed over above 800Hz” that why do you use the 300Hz horn? I personally find that most 300 Horns are conceptually faulty as they have too large bell for the typical 2”-4”compression driver. If you have a chance then try to load your 2440, crossed at 800Hz into 400-450Hz horn instead of 300Hz. You will have many benefits: a shorter horn, twice smaller horn, better HF, wider dissipation pattern, less throat reactance (less air mass in the bell), better transient response, way less possibility to get horn’s honk, ability to use “more interesting” low pass filter in your upperbass channel…."

"What I have seen was that people load their compression drivers into the belly of the oversized horns. As the result they do not ingrate their upperbass channel with the horn-loaded mid-channels but they integrate their upperbass channel with those artificial lower-mid frequency noise coming from the large belly of the oversized horns, that horns that in their case act as the “virtual resonators” and produce more the “large barrel sound” then actual useful sound."

|

|

|

|

Posted by Wojtek on

09-14-2006

|

Hi there

I can see Romy's face when he's trying to figure out Martin's time alignment strategy;0) I have Martin's 204 Hz horn with Fostex 208 E Sig. These horns are to be big to properly integrate with anything. They are OK with Fostex Lowther drivers if one is willing to accept a compromise. I'd be interested in extension adapter from 8" to 3.5" , 4" and try Fostex as a mid-bass and add 400-400Hz mid horn and tweeter. I have a little crazy idea of loading my big-ass 204 Hz horn (closed throat) with two EV 828 HF reentrant compound drivers from EV Patrician IV. They have 2" phenolic diaphragms and are crossed at 200 Hz/6db in Pats. Anyway nice to see a little hornopornography here. Regards. W

|

|

|

|

Posted by Romy the Cat on

09-15-2006

|

|

Wojtek,

I do not think that Martin has any time alignment strategy. You see, the necessity for time alignment is a basic fundamental principle, and particularly in horns that spin phase like helicopter. However, in many instances the horns are juts not alignable in context of the give real-estate and context of selected horns and the given room layout.

What I usually look for is a sensibility, balance and reasoning. I have seen people pile up horns without any consideration how then would be use. The horns dimension, the phasing, the room reverberation time, the characters of the drivers, the acoustic and electric filters and many many other aspects should be well thought out before people begin to cut the wood. Generally, following some abstract concept even they were ration concepts do not work in horns. The only thing that does work is to do things, observe results and react to the results with appropriate direction of actions. That is why looking at a properly implemented and performing installation it is always an intellectual pleasure as a well behaving installation exposes a lot of underlying thinking and a lot of underlying rational. It is like reading somebody’s diary-novel, when following what was expressed you can image what “might be said” or what was implied. Rgs,

Romy the caT

|

|

|

|

Posted by angeloitacare-idiot on

09-15-2006

|

hi

are your horns available for purchase ? what is the price ?

thanks Angelo

|

|

|

|

Posted by cv on

10-03-2006

|

Hi all

If anyone wants to go for a UK or US group buy on these, please let me know and we can co-ordinate with Martin. Likewise, if you can't find his email address online, drop me an email via the site and I will put you in touch.

Cheers,

cv

|

|

|

|

Posted by cv on

10-12-2006

|

|

Hope Romy won't mind a semi-commercial update...

Martin will be selling these for AUD$ 1140, which is about $860 at current rates. He will have a website soon.

Any more takers from the UK?

Best,

cv

|

|

|

|

Posted by Romy the Cat on

10-12-2006

|

cv wrote: cv wrote: | Hope Romy won't mind a semi-commercial update...

Martin will be selling these for AUD$ 1140, which is about $860 at current rates. He will have a website soon.

Any more takers from the UK? |

|

I do not do commerce on my site and therefore I perfectly fine with anybody advertising anything. What I learned is that when people prohibit any commercial context within their site then it is indubitable evidence that the owners of the site make commerce under the hood.

Regardless the subject. The 160Hz horns for $860? It is very reasonable price as far can tell. The last year or two the prices for horns went up, or the horn turner’s labor went up… well everything went up since this damn Bush. I wonder why Martin is able to maintain the reasonable price: become the Australians have no idiots in their government or because those horn are light and less expansive to male. (I do not know what material they use) Rgs,

Romy the caT

|

|