|

Posted by Romy the Cat on

05-21-2010

|

|

fiogf49gjkf0d

Preparing for my Midbass Channel projects

http://www.romythecat.com/Forums/ShowPost.aspx?postID=13597

…I did inventory if the drivers that I might use for it. I never did it before as the all were in different storages, now they are in one basement – very convenient. It is not secret that I intent to use Vitavox 15 inch drivers that I consider ridiculously good. I have a few 151, a few 10/40 and I one 154 and one that I am not sure number. The 151 and 10/40 are my best candidate and, boy, I just love the scarp their belly – the respond as a deck of 300 year cello. Here is a ketch however that I discovered – they all are different. If I take 4 of my 151 then each of them has cone slightly different from other. Sure they are 50 years old drivers and then were used during the time in different application/locations and aged differently. Still, they feel like have slightly different cone and then have very slightly different harmonics of cone’s response. They all have that Vitavoxy super-soft throaty tone but very-very different inflections into the gone.

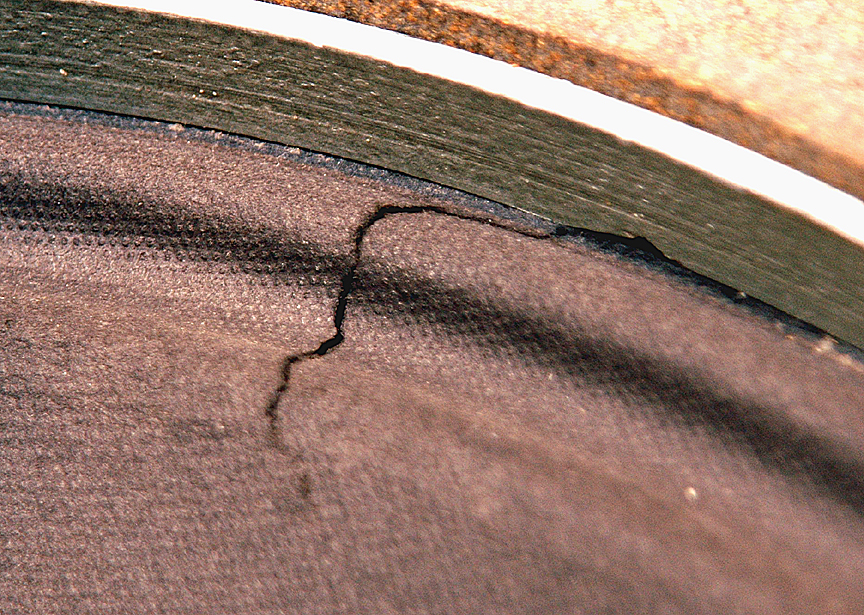

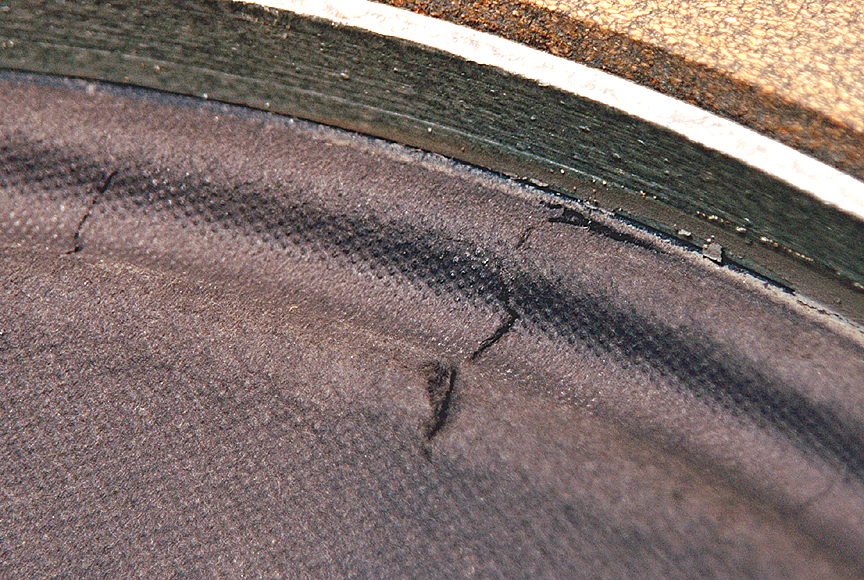

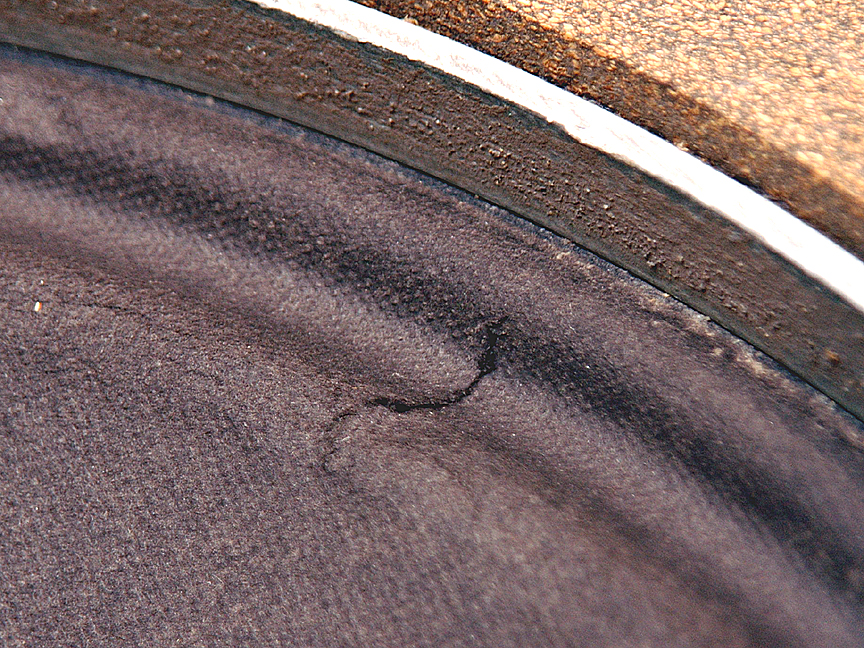

I have new 151 and 10/40, I mean so new that it never was removed from original box, something so called “in paper” or as Russians say “a fly did not fuck on it”. I have some of the drivers have worn cone with some marks of cracks and tears. And of cause as it was very much expected according to the Murphy’s Law – the best sounding drivers are the pair that has max cracks. A one of them, that has even a huge damage as 1” rip is my absolutely best driver – tonally it is totally out of this word. It is possible that it has to do with moisture and other conditions. However, prior to selecting a pair of the drivers I will be using in my Midbass Channel I would like to fix my drivers that need to be fixed.

So, here is the question – how properly to deal with minor cracks, rips and tears and do not ruin so precious driver’s sound?

Sure, the reckoning is out of question. The regular glues and patches that drivers fixing companies are using are out of picture. In a past I have a good success to apply women stockings over the tears soaked in the Elmer Glue of some kind of wood glue. It was long time ago and I guess at that time those types of glues were made from cellulose. It was good for driver but nowadays those glues are made from petroleum. The problem with petroleum glue is that it maintains good texture for some time – a few month and then become too dry – not good for my application.

The best result I was able to get when I was repairing my Altec 15G drivers. After long research and a lot of consulting with different people I came up with my own mixture. I use cigarette paper that I soaked in table tennis glue, while did soaking I add some chalk dust. It was very good but it was very frigidly and was not working for a long time, or work only on very-very small cuts. However, it was for a while back and at that time I did not have as high objectives as I have to my 15” driver now.

My objectives are to have a patch or in in-cone filler that would absolutely not change the response of the driver if I move my nail across the cone and across the fixed location. Do anybody has any “secretive” and proven methodology that you might advise. I hears a lot of good feedback about hatin (what the roach’s legs are mane from) but hatin is not glueee and would need to be accompanied with some adhesive substance that would not ruin nether up the driver mechanical texture not the speed of sound across the cone.

Rgs, The Cat

|

|

|

|

Posted by Markus on

05-21-2010

|

|

fiogf49gjkf0d  Romy the Cat wrote: Romy the Cat wrote: | |

Have you ruled out demagnetisation as a factor? I'd consider re-magnetizing the drivers before settling on a solution.

|

|

|

|

Posted by el`Ol on

05-21-2010

|

|

fiogf49gjkf0d  Romy the Cat wrote: Romy the Cat wrote: | The regular glues and patches that drivers fixing companies are using are out of picture. In a past I have a good success to apply women stockings over the tears soaked in the Elmer Glue of some kind of wood glue. It was long time ago and I guess at that time those types of glues were made from cellulose. It was good for driver but nowadays those glues are made from petroleum. The problem with petroleum glue is that it maintains good texture for some time – a few month and then become too dry – not good for my application. |

|

Pritt and probably other glue sticks are made of natural polysaccharides. I have glued cones with Pritt and rice paper, but I can't say anything about long term stability.

|

|

|

|

Posted by Paul S on

05-21-2010

|

|

fiogf49gjkf0d Romy, it sounds like you are well into this, already. We used to use extremely sheer silk with our "secret" doping formulae. The key is to keep it as thin and flexible as possible. Today, I would look for resin/glue with "fibers" in it to bridge the rip itself. Maybe the "dope" with silk or fiberglass fibers mixed into it? I think they do make a glue from crab shells, or something like that. Old-style "hot pot" furniture glue is of horse hooves, and it should work, but you would have to be careful not to glop it. Likewise, rabbit's foot glue. A good bond to the edges of the tear, with fibers bridging and connecting both sides of the tear, with no extra layer of material over the surface of the cone, would be ideal. Bridge the gap and back the repair with blue tape or "architect's" tape on the side opposite the repair until the glue sets up, then remove the backing.

Orange County Speakers is the Southern California outfit that does a lot of the pro gear, and they also sell some supplies for all kinds of drivers. Also, they have been around for a while, and they know people, including the kind of weird-os you might want to contact. I suppose we don't generally look to pro gear for tone; but it's a lead...

Don't forget Steve and Rich, aka, The Cogent Boys...

Best regards,

Paul S

|

|

|

|

Posted by msaudio on

05-21-2010

|

|

fiogf49gjkf0d Over the last 30 years i have used GC electronics speaker repair adhesive and never had a problem with it. There are 2 styles, rubber base and see threw, pt# 10-4302 for the rubber base it is the only one for cloth surrounds because it will bend with the speaker without tearing. I donot have the part number for the one that dries hard witch is see threw, your GC electronics dealer will no the number. Most of the electronic wholesale houses carry it. It also would be nice to give your new project a chance of being great if you would use the same part number cones on your LF drivers, so you donot have low resonance problems. Could be a better idea to replace all the cones with same part number so you have a fighting chance of perfection. I would not atempt a halfass job, starting from scratch. I would sale them on ebay, then use that money to buy matched one's, it don't have to be same brand to be good. Preaching Horn Religion MSAUDIO

|

|

|

|

Posted by haralanov on

05-22-2010

|

|

fiogf49gjkf0d  Romy the Cat wrote: Romy the Cat wrote: | | A one of them, that has even a huge damage as 1” rip is my absolutely best driver – tonally it is totally out of this word. It is possible that it has to do with moisture and other conditions. |

|

Romy, would you post detailed picture of the rip and another one of the whole cone?

|

|

|

|

Posted by Romy the Cat on

05-22-2010

|

|

fiogf49gjkf0d  haralanov wrote: haralanov wrote: | | Romy, would you post detailed picture of the rip and another one of the whole cone? |

|

Actually, after a thorough investigation I concluded the I have only one driver damage 151… and this one that sound the best….

The cAT

|

|

|

|

|

|

|

Posted by tuga on

05-23-2010

|

|

fiogf49gjkf0d Romy,

Why not contact a book restoration company?

They might have the key.

Cheers,

Ric

|

|

|

|

Posted by el`Ol on

05-23-2010

|

|

fiogf49gjkf0d  tuga wrote: tuga wrote: |

Why not contact a book restoration company?

They might have the key. |

|

I once saw a documentation where they used rice paper and rice starch glue.

Will of course require many layers for a large cone and will have some stiffness.

|

|

|

|

Posted by be on

05-23-2010

|

|

fiogf49gjkf0d

Romy:

-A one of them, that has even a huge damage as 1” rip is my absolutely best driver-

Maybe it is the best driver, not despite of the crack, but because of it??

Rgds.

be

|

|

|

|

Posted by Paul S on

05-24-2010

|

|

fiogf49gjkf0d Here is a repair guy who actually sounds like he's thought this through: http://www.timeelect.com/vinsp.htm

Not knowing the guy at all, I can't say if he'd be open to having you poke and prod him about methods. He does appear to have long experience, whatever that's worth.

Best regards,

Paul S

|

|